Innovative Fasteners and Machining Solutions for Intricate Styles

Innovative Fasteners and Machining Solutions for Intricate Styles

Blog Article

Mastering the Art of Bolts and Machining: Technologies and Finest Practices

In the realm of commercial manufacturing and engineering, the mastery of fasteners and machining is a keystone of making certain structural stability, capability, and longevity in different applications. Join us as we explore the most current developments and dig into the nuanced globe of grasping bolts and machining, uncovering crucial understandings and techniques that can raise your method to engineering remedies.

Development of Attachment Technologies

Throughout the industrial transformation and into the contemporary period, the evolution of securing modern technologies has actually been noted by continual innovations in efficiency and reliability. Fasteners, such as bolts, screws, and rivets, play a critical duty in different markets, including auto, aerospace, building and construction, and electronics. The demand for more powerful, extra long lasting, and easier-to-install fastening remedies has driven technology in the field.

One considerable advancement has been the change in the direction of accuracy machining methods to create fasteners with higher tolerances and premium efficiency. This change has actually made it possible for makers to generate fasteners that satisfy stringent top quality requirements and deal boosted resistance to deterioration and fatigue.

In addition, the intro of innovative materials, such as titanium alloys and composites, has actually reinvented the capabilities of bolts. Fasteners and Machining. These materials offer remarkable strength-to-weight ratios, making them perfect for applications where minimizing weight is critical without compromising architectural honesty

Improvements in Machining Techniques

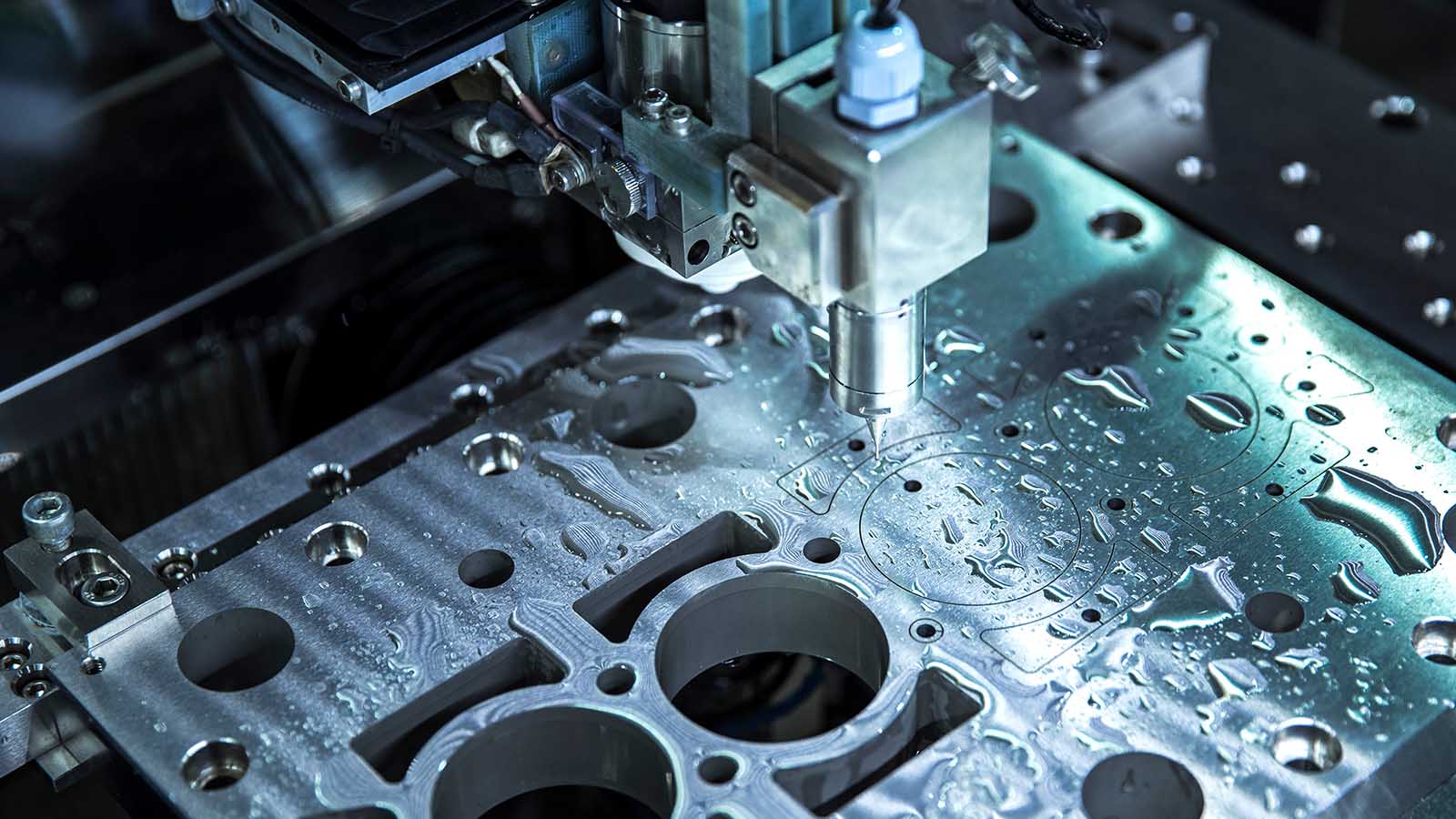

In the realm of commercial manufacturing, the continuous evolution of machining techniques has actually led the method for unmatched accuracy and performance in the production of bolts. This accurate control makes it possible for manufacturers to produce complex and detailed fastener styles with simplicity.

Furthermore, the adoption of multi-axis machining centers has made it possible for simultaneous cutting procedures from different angles, additionally improving efficiency and minimizing production times. By utilizing these innovative machining approaches, producers can fulfill the enhancing need for high-quality fasteners while preserving cost-effectiveness in their operations.

Selecting the Right Fastener Materials

Picking the appropriate product for bolts is an essential choice that considerably affects the performance and longevity of the constructed components. When picking the appropriate bolt product, numerous aspects should be thought about to make sure the sturdiness and reliability of the final product. The product selected should work with the ecological problems the bolts will be go now subjected to, such as temperature variations, moisture levels, and harsh elements.

Usual materials utilized for fasteners consist of stainless steel, carbon light weight aluminum, titanium, and steel, each offering distinct residential properties that match various applications. Carbon steel is a page cost-effective choice ideal for numerous general-purpose applications.

Enhancing Accuracy in Machining

Accomplishing optimal precision in machining is necessary for guaranteeing the top quality and performance of machined components. To enhance precision in machining, manufacturers utilize a selection of advanced techniques and modern technologies.

Along with CNC machining, the usage of advanced cutting devices and tool holders can additionally considerably boost accuracy. Top quality cutting tools with advanced finishes reduce friction and wear, causing a lot more specific cuts and dimensional precision. Carrying out stringent top quality control procedures throughout the machining procedure, such as normal evaluations and calibration of equipment, aids keep regular precision degrees. By focusing on precision in machining, manufacturers can attain premium item top quality, tighter resistances, and boosted total efficiency of machined elements.

Best Practices for Bolt Setup

Accuracy in machining plays an important role in ensuring the dependability and long life of fastener setups. One essential element is the appropriate choice of fasteners based on the particular application demands when it comes to ideal methods for fastener installment. Making use of the correct kind, dimension, and material of fastener is necessary to guarantee ideal efficiency and longevity. Fasteners and Machining. In addition, it is critical to adhere to manufacturer guidelines and advised torque values during the installment procedure to avoid under-tightening or over-tightening, which can bring about early fastener failure.

Additionally, making sure that the bolt strings check that are tidy and totally free of debris prior to installation is vital to attaining a secure and effective link. Using thread-locking compounds or washing machines can likewise improve the security of the fastener setting up. Regular evaluations and upkeep of fasteners post-installation are recommended to determine any possible problems at an early stage and stop pricey repairs or substitutes in the future. By adhering to these ideal methods, producers can enhance the stability and efficiency of their fastener installments.

Conclusion

To conclude, the evolution of attaching innovations and improvements in machining approaches have actually dramatically boosted the performance and effectiveness of bolt installation procedures. By selecting the best bolt materials and improving precision in machining, manufacturers can attain optimum cause their operations. Complying with finest practices for bolt setup is critical in making sure the toughness and integrity of assemblies. On the whole, mastering the art of fasteners and machining involves continual innovation and adherence to finest techniques.

In the realm of commercial manufacturing, the continual evolution of machining methods has led the way for extraordinary precision and efficiency in the production of fasteners.Precision in machining plays a vital function in ensuring the integrity and long life of bolt installments. When it comes to ideal techniques for bolt setup, one vital facet is the correct choice of fasteners based on the details application needs. By picking the appropriate fastener materials and enhancing precision in machining, makers can achieve ideal outcomes in their procedures. Generally, understanding the art of fasteners and machining entails continual technology and adherence to best techniques.

Report this page